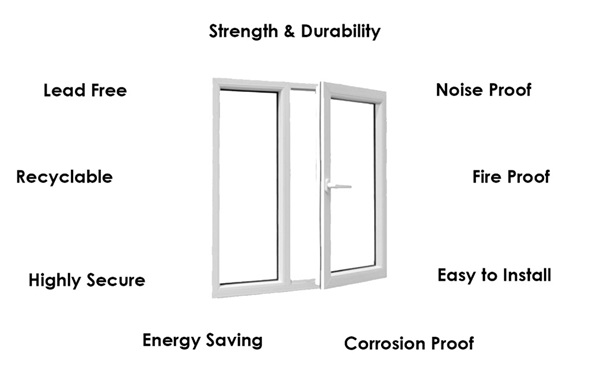

The engineering involved behind uPVC windows: Key benefits for homeowners

There is a lot of information being mentioned about the benefits of uPVC windows. But there is not much explanation about the reasons why this trend is popular. Knowing the engineering involved behind its success will make you understand the reasons to prefer uPVC windows for a home or commercial space.

As one of the reputed uPVC windows manufacturers in India, VEKA brings international technology and experience to its customers. We explain in simple terms the engineering involved so that the key benefits for homeowners are very clear.

As uPVC material is dominating compared to others, knowing its value is important. VEKA has a factory in Hyderabad, which is the main hub where the windows and doors are prepared in a customised manner. The constructions are done keeping in mind several factors and its all-India network to serve customers.

4 important processes are applied to achieve high-quality products. They are:

- Extrusion of profiles

- Choices of glass panes

- Hardware and accessories

- Quality control before the products are installed

Each product is designed by an expert team that is qualified for the engineering procedures. The products also meet international standards for Indian property. Processes involve several phases:

- Creation of air-tight seals during cold weather.

- Minimising the heat reduction in humid places.

- Handling noise pollution to keep interiors soundproof.

- Safety and security are provided with locks and handles.

- Hardware and other accessories are robust enough to last a long time.

Due to reducing the environmental impact, our engineering team uses materials like uPVC, which are recyclable and create less wastage. All uPVC windows for homes and other commercial properties undergo stringent quality testing before they are sent for installation. The testing is done for:

- The durability and functioning of the windows

- Air & water tightness

- Aesthetic appeal for the property

- Structural stability against wind load & other forces

Raw materials are chosen carefully. The uPVC material is picked from qualified vendors with certification. It sets the ball rolling for the rest of the design to meet the specific standards.

Hardware and accessories also form an integral part of engineering procedures. They also add to the functionality and the overall appearance of the product. This stage involves the choice of glass and screens for keeping away mosquitoes and other insects. The glass choice is important to keep a good balance between natural and indoor light options. They also matter as energy efficiency is affected. In warm months, good insulation can reduce AC bills in Indian homes. A low emission quality can keep the home warmer in the cold months.

The choice of handles given by uPVC windows manufacturers in India differ. VEKA offers handles not only for opening and closing the windows, but good quality handles are designed for locking and safety as well. As they are used daily, they need to be sturdy and provide security to the owners. For instance, multiple locking systems are preferred by commercial property owners. It gives them the peace of mind when business is shut at the end of the day.

VEKA provides benefits of uPVC windows along with the procedures that make them great. Our engineering team provides a brief before a project is taken and also when the installations are being done. Should you need more clarity, do let us know. We can schedule a visit and discussion at your convenience.