Understanding Profile Extrusion for uPVC Windows and Doors

As more people in India adopt new systems like uPVC windows and doors, there is a curiosity to perceive how it works. Understanding the process will encourage us to appreciate the qualities and determine an informed choice before ordering. The uPVC windows and doors extrusion profiles undergo a sophisticated manufacturing process in state-of-the-art factories. Let’s enter the VEKA factory in Hyderabad to gain more insight into its making.

The manufacturing of uPVC windows and doors profile in Hyderabad is exactly the way it works for the company’s fabricators across India. No matter where you are located, order a customized mounting for an apartment, farmhouse or even office.

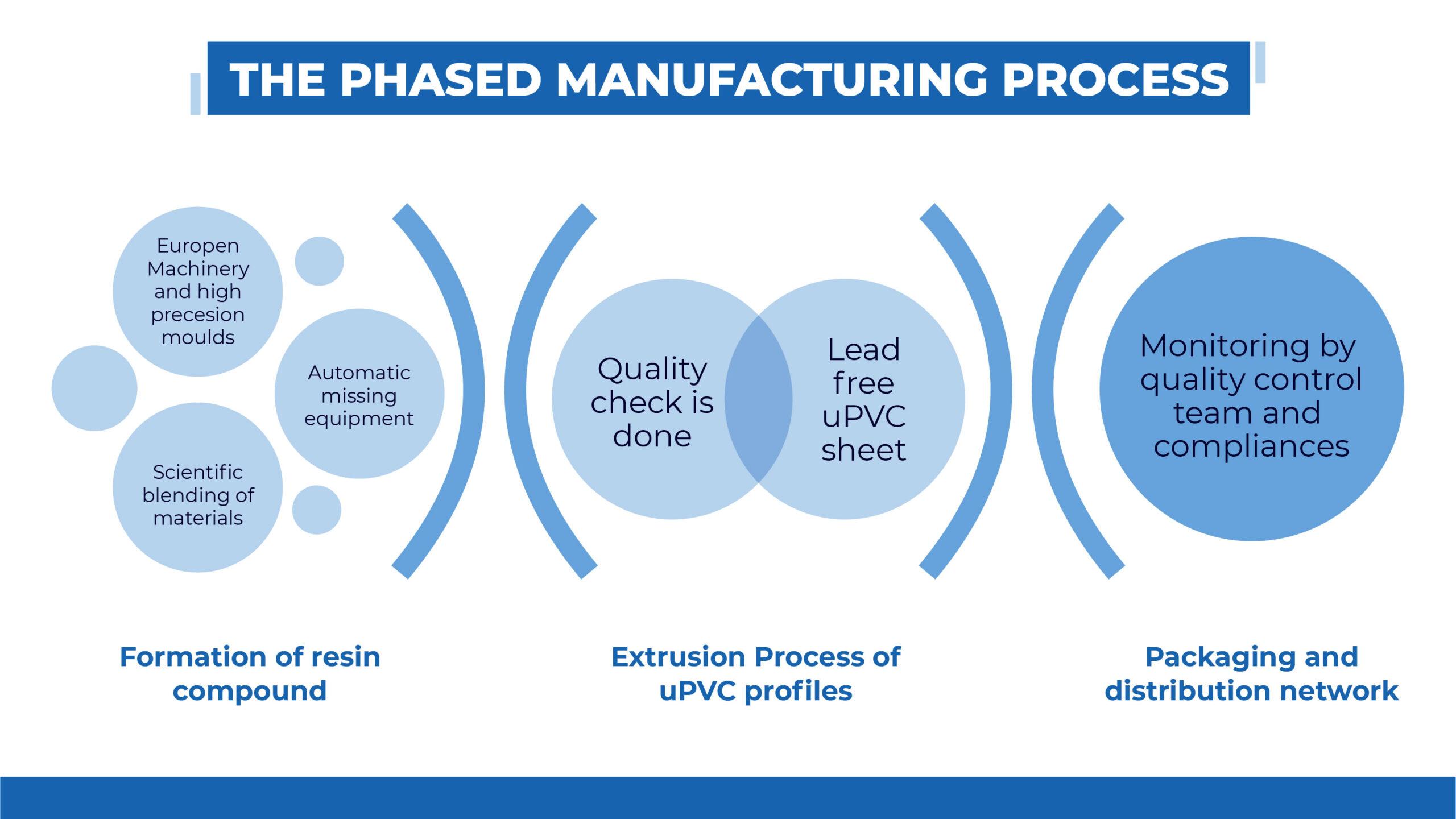

The Phased Manufacturing Process

Secrets to Creating Extrusion Profiles

VEKA’S large factory is spacious and equipped with modern machinery. Workers use various manual and automated processes to make unique profiles in various disciplined stages. We use adequate raw materials which undergo checks. In this way the quality control begins with procurement of uPVC which is lead-free and with high titanium levels. The sourcing is done from across the world to ensure the final and durable product serves the purpose. For the process of extrusion, the finest machinery is operated in the manufacturing hub. The workers are experienced to blend the ingredients for top results. Due to the automation systems used for production the dimensional accuracy and measurements are exact. A quality control team ensures every stage is approved before moving on to the next one.

Workflow for Window Making

Engineering the archetype uPVC windows and doors extrusion profiles remain a skilled commercial activity. Many thoughts go into the design, making and eventual packaging. While determining the raw materials for extrusion, a vital factor is the temperature it will serve. This directly impacts how long the casement design will last. Operating the right machinery to cut and weld matters because of the exact fitting on site. Only trained hands are used in the uPVC windows and doors profile in Hyderabad. The process includes the choice of glass, gasket and sealants. The hardware accessories which will be added will be worth the creation of the profile.

The blending section is where the raw materials are collected. Each extrusion demands a specific amount of chemical composition. This is expected to make the window UV-resistant, and bring white balance.

VEKA’S window factory in Hyderabad employs a combination of skilled hands, advanced equipment and machinery to deliver the end product. Testing is done before handing the final frames to engineers. Why not take a virtual tour before you place an order with us today?